Eventually, self-driving cars will arrive. But until then, here’s a look at what will drive that progression.

The next arrow of development is set for automotive

We all have seen it. We all have read about it in your front-center technology news outlets. The next forefront for technology will take place in the vehicle. The growing market fitted with the feature deviation trend does not appeal to the vision of customizing more traditional un-connected, oiled and commonly leveraged chassis vehicles of today. Instead, ubiquity in smartphones have curved a design trend, now mature while making way for the connected car platform. The awaiting junction is here for more integration of the automotive software stack. Opportunities for the connected car market are huge, but multiple challenges still exist. Life-cycles in the development of automotive and the mobile industry are a serious barrier for the future of connected cars. Simply, vehicles take much longer to develop than smartphones other portable gadgetry. More integration from vendors and suppliers are involved with the expertise to seamlessly fit the intended blueprint of the design. In fact, new features such as the operating system are becoming more prevalent, while the demand for sophisticated and centrally operated embedded systems are taking the height of the evolution. This means more dependence on integration of data from various channels, actuators, and sensors — the faculty to operate all the new uses cases such as automatic emergency response systems are functionality requiring more SoC embedded system requirements.

What is happening now?

People. Process. Governance. Adoption. Let’s look at the similarities stemmed from change. We are going to witness new safety laws and revised regulations coming through the industry. These new laws will dictate the demand for connectivity. Indeed, drawing importance this 2015 year with the requirement set by 2018, European Parliament voted in favor of eCall regulation. Cars in Europe must be equipped with eCall, a system that automatically contacts emergency services directing them to the vehicle location in the event of an emergency. The automotive and mobile industries have different regional and market objectives. Together, all the participants in both market segments will need to find ways to collaborate in order to satisfy consumer connectivity needs. Case in point, Chrysler has partnered with Nextel to successfully connect cars like their Dodge Viper, while General Motors uses AT&T as its mobile development partner.

What is resonating from the sales floor and customer perspective?

The demand is increasing for more sophistication and integration of software in the cabin of cars. This is happening from the manufacturer to the supplier network then to the integration partners — all are becoming more engaged to achieve the single outcome, pacing toward the movement to the connected car. Stretched as far as the actual retail outlets, auto dealers are shifting their practice to be more tech savvy, too. The advent of the smart vehicle has already dramatically changed the dealership model, while more transformation awaits the consumer.

On the sales floor as well as the on-boarding experience, sales reps must plan to spend an hour or more teaching customers how to use their car’s advanced technology. But still, these are only a few mentioned scenarios where things have changed in relation to cars and how they are sold and even to the point of how they are distributed, owned, and serviced. One thing for certain, though, is that the design and user trend are intersecting to help shape the demand and experience a driver wants in the connected car. This is further bolstered by the fast paced evolution of smartphones and the marketing experiences now brought forth by the rapid adoption and prolific expansion of the mobile industry tethered by their very seamless and highly evolved experiences drawn from their preferred apps.

Today, customer experiences are becoming more tailored while users, albeit on the screen or engaged with their mobile devices are getting highly acquainted with the expectation of “picking up from where I left off” regardless of what channel, medium, device, or platform. Seamless experiences are breaking through the market. We witness Uber, where users initialize their click on their smartphone then follows by telemetry promoted from Uber drivers and back to the users smart phone. In fact, this happens vis versa, Uber driver’s have information on their console showing customer location and order of priority. Real life interactions are being further enhanced by real-time data, connecting one device to draw forth another platform to continue the journey. Transportation is one of the areas where we can see real-time solutions changing our day-to-day engagement. Some of these are being brought forth by Atmel’s IoT cloud partners such as PubNub where they leverage their stack in devices to offer dispatch, vehicle state, and geo fencing for many vehicle platforms. Companies like Lixar, LoadSmart, GetTaxi, Sidecar, Uber, Lyft are using real-time technologies as integral workings to their integrated vehicle platforms.

Cars are becoming more of a software platform where value chain add-ons tied to an ecosystem are enabled within the software tethered by the cloud where data will continue to enhance the experience. The design trajectory for connected cars follow this software integration arrow. Today, the demand emphasizes mobility along with required connectivity to customer services and advanced functions like power management for electric vehicles, where firmware/software updates further produce refined outcomes in the driver experience (range of car, battery management, other driver assisted functionalities).

Carmakers and mobile operators are debating the best way to connect the car to the web. Built-in options could provide stronger connections, but some consumers prefer tethering their existing smartphone to the car via Bluetooth or USB cable so they can have full access to their personal contacts and playlists. Connected car services will eventually make its way to the broader car market where embedded connections and embedded systems supporting these connections will begin to leverage various needs to integrate traditional desperate signals into a more centrally managed console.

Proliferation of the stack

The arrow of design for connected cars will demand more development, bolstering the concept that software and embedded systems factored with newly-introduced actuators and sensors will become more prevalent. We’re talking about “software on wheels,” “SoC on wheels,” and “secured mobility.”

Design wise, the cost-effective trend will still remain with performance embedded systems. Many new cars may have extremely broad range of sensor and actuator‑based IoT designs which can be implemented on a single compact certified wireless module.

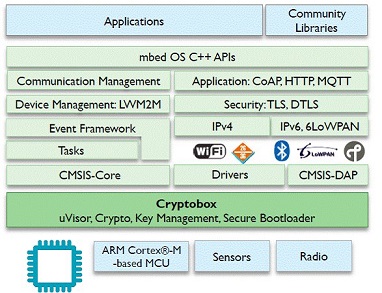

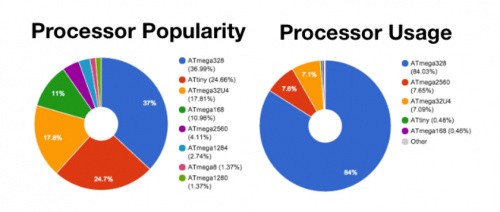

Similarly, having fastest startup times by performing the task with a high-performance MCU vs MPU, is economic for a designer. It can not only reduce significant bill of materials cost, development resources, sculpted form factor, custom wireless design capabilities, but also minimize the board footprint. Aside from that, ARM has various IoT device development options, offering partner ecosystems with modules that have open standards. This ensures ease of IoT or connected car connectivity by having type approval certification through restrictive access to the communications stacks.

Drivers will be prompted with new end user applications — demand more deterministic code and processing with chips that support the secure memory capacity to build and house the software stack in these connected car applications.

Feature upon feature, layer upon layer of software combined with characteristics drawn from the events committed by drivers, tires, wheels, steering, location, telemetry, etc. Adapted speed and braking technologies are emerging now into various connected car makes, taking the traditional ABS concept to even higher levels combined with intelligence, along with controlled steering and better GPS systems, which will soon enable interim or cruise hands-free driving and parking.

Longer term, the technological advances behind the connected car will eventually lead to self-driving vehicles, but that very disruptive concept is still far out.

Where lies innovation and change is disruption

Like every eventual market disruption, there will be the in-between development of this connected car evolution. Innovative apps are everywhere, especially the paradigm where consumers have adopted to the seamless transitional experiences offered by apps and smartphones. Our need for ubiquitous connectivity and mobility, no matter where we are physically, is changing our vehicles into mobile platforms that want us users to seamlessly be connected to the world. This said demand for connectivity increases with the cost and devices involved will become more available. Cars as well as other mobility platforms are increasingly becoming connected packages with intelligent embedded systems. Cars are offering more than just entertainment — beyond providing richer multimedia features and in-car Internet access. Further integration of secure and trusted vital data and connectivity points (hardware security/processing, crypto memory, and crypto authentication) can enable innovative navigation, safety and predictive maintenance capabilities.

Carmakers are worried about recent hacks, especially with issues of security and reliability, making it unlikely that they will be open to every kind of app. They’ll want to maintain some manufactured control framework and secure intrusion thwarting with developers, while also limiting the number of apps available in the car managing what goes or conflicts with the experience and safety measures. Importantly, we are taking notice even now. Disruption comes fast, and Apple and others have been mentioned to enter this connected car market. This is the new frontier for technological equity scaling and technology brand appeal. Much like what we seen in the earlier models of Blackberry to smartphones, those late in the developmental evolution of their platforms may be forced adrift or implode by the market.

No one is arguing it will happen. Eventually, self-driving cars will arrive. But for now, it remains a futuristic concept.

What can we do now in the invention, design and development process?

The broader output of manufactured cars will need to continue in leveraging new designs that take in more integration of traditional siloed integration vendors so that the emergence of more unified and centrally managed embedded controls can make its way. Hence, the importance now exists in the DNA of a holistically designed platform fitted with portfolio of processors and security to take on new service models and applications.

This year, we have compiled an interesting mixture of technical articles to support the development and engineering of car access systems, CAN and LIN networks, Ethernet in the car, capacitive interfaces and capacitive proximity measurement.

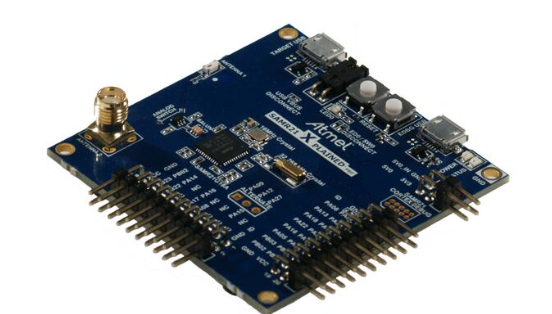

In parallel to the support of helping map toward the progress and evolution of the connected car, a new era of design exists. One in which the platform demands embedded controls to evenly match their design characteristics and application use cases. We want to also highlight the highest performing ARM Cortex-M7 based MCU in the market, combining exceptional memory and connectivity options for leading design flexibility. The Atmel | SMART ARM Cortex-M7 family is ideal for automotive, IoT and industrial connectivity markets. These SAM V/E/S family of microcontrollers are the industry’s highest performing Cortex-M microcontrollers enhancing performance, while keeping cost and power consumption in check.

So are you designing for the latest automotive, IoT, or industrial product? Here’s a few things to keep in mind:

- Optimized for real-time deterministic code execution and low latency peripheral data access

- Six-stage dual-issue pipeline delivering 1500 CoreMarks at 300MHz

- Automotive-qualified ARM Cortex-M7 MCUs with Audio Video Bridging (AVB) over Ethernet and Media LB peripheral support (only device in the market today)

- M7 provides 32-bit floating point DSP capability as well as faster execution times with greater clock speed, floating point and twice the DSP power of the M4

We are taking the connected car design to the next performance level — having high-speed connectivity, high-density on-chip memory, and a solid ecosystem of design engineering tools. Recently, Atmel’s Timothy Grai added a unveiling point to the DSP story in Cortex-M7 processor fabric. True DSPs don’t do control and logical functions well; they generally lack the breadth of peripherals available on MCUs. “The attraction of the M7 is that it does both — DSP functions and control functions — hence it can be classified as a digital signal controller (DSC).” Grai quoted the example of Atmel’s SAM V70 and SAM V71 microcontrollers are used to connect end-nodes like infotainment audio amplifiers to the emerging Ethernet AVB network. In an audio amplifier, you receive a specific audio format that has to be converted, filtered, and modulated to match the requirement for each specific speaker in the car. Ethernet and DSP capabilities are required at the same time.

“The the audio amplifier in infotainment applications is a good example of DSC; a mix of MCU capabilities and peripherals plus DSP capability for audio processing. Most of the time, the main processor does not integrate Ethernet AVB, as the infotainment connectivity is based on Ethernet standard,” Grai said. “Large SoCs, which usually don’t have Ethernet interface, have slow start-up time and high power requirements. Atmel’s SAM V7x MCUs allow fast network start-up and facilitate power moding.”

Atmel has innovative memory technology in its DNA — critical to help fuel connected car and IoT product designers. It allows them to run the multiple communication stacks for applications using the same MCU without adding external memory. Avoiding external memories reduces the PCB footprint, lowers the BOM cost and eliminates the complexity of high-speed PCB design when pushing the performance to a maximum.

Importantly, the Atmel | SMART ARM Cortex-M7 family achieves a 1500 CoreMark Score, delivering superior connectivity options and unique memory architecture that can accommodate the said evolve of the eventual “SoC on wheels” design path for the connected car.

How to get started

- Download this white paper detailing how to run more complex algorithms at higher speeds.

- Check out the Atmel Automotive Compilation.

- Attend hands-on training onboard the Atmel Tech on Tour trailer. Following these sessions, you will walk away with the Atmel | SMART SAM V71 Xplained Ultra Evaluation Kit.

- Design the newest wave of embedded systems using SAM E70, SAM S70, or SAM V70 (ideal for automotive, IoT, smart gateways, industrial automation and drone applications, while the auto-grade SAM V70 and SAM V71 are ideal for telematics, audio amplifiers and advanced media connectivity).

[Images: European Commission, GSMA]

The

The